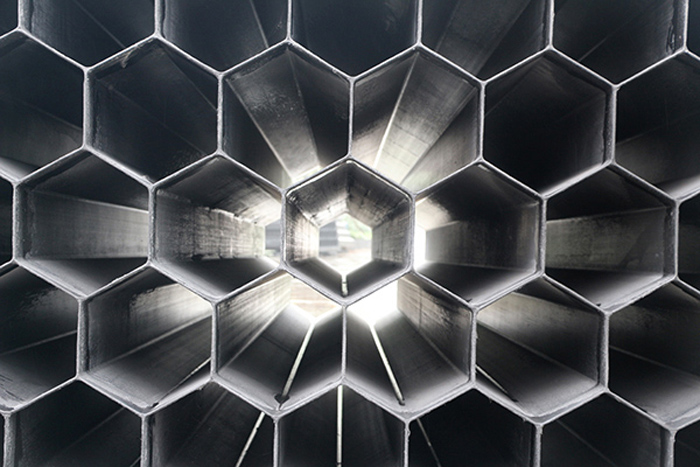

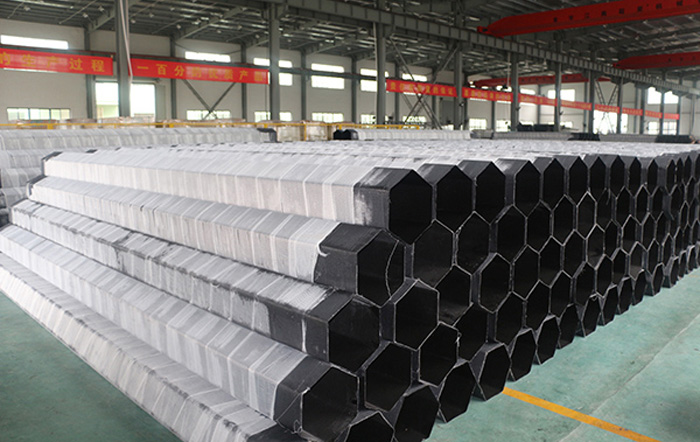

Honeycomb anode tube

FRP is non-metallic material, and FRP itself is not conductive. The conductivity of the conductive FRP anode tube is achieved by adding conductive agent (Shi Mofen) to the resin and adding carbon fiber felt on the inner surface of the tube.

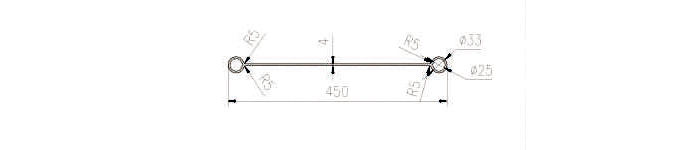

The hexagonal anode tube produced by our company can reach 6 <100 distance resistance, reaching the front row level of the same industry (the smaller the resistivity value is, the better the conductivity is). The carbon fiber surface felt can achieve good electrical conductivity of the inner surface of the insulating composite anode tube. We strictly adopt the carbon fiber surface felt material of 30g /m2 specification.

The size of the tangential circle in the anode tube of the hexagon is 350mm, 360mm.

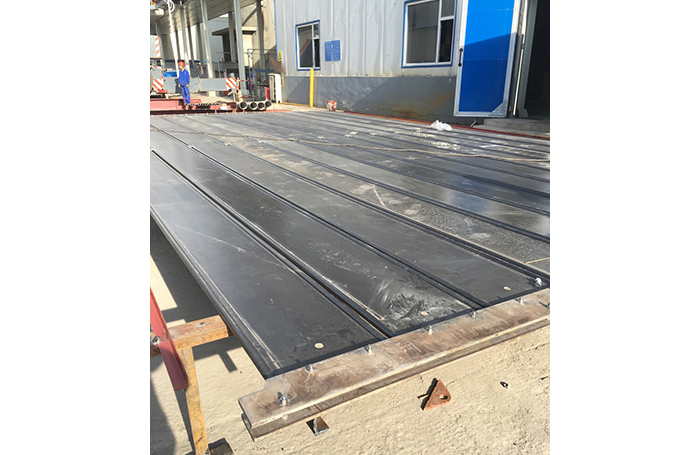

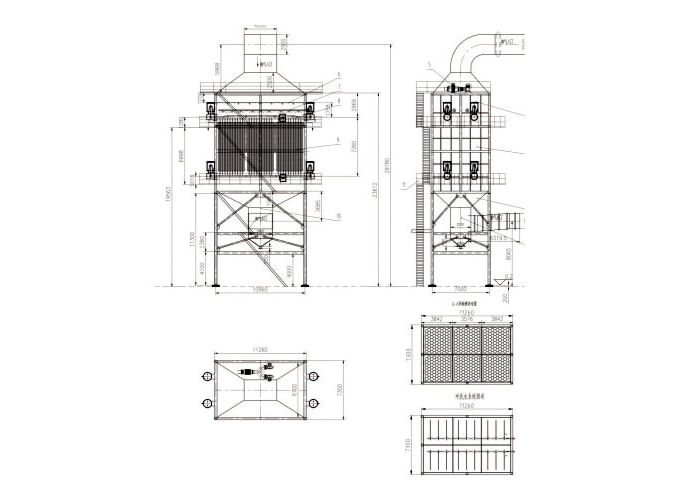

The anode system for the core components of the wet electrostatic precipitator needs high acid corrosion resistance, high conductivity, easy cleaning of dust, and easy maintenance. Based on the production of the first generation anode tube, we overcome the difficult problem of single tube replacement after assembling module. We developed the two generation anode plate structure, and successfully developed the production process and production equipment of anode plate. The advantages and use environment of the anodic plate of FRP

First, corrosion resistance: the glass fiber reinforced plastic anode plate is made of vinyl resin pultrusion. It has good corrosion resistance and can withstand various levels of acid, alkali, organic solvents, salts and many other gas and liquid medium corrosion.

Two, light weight and high strength: glass fiber reinforced plastic anode plate is reinforced by composite materials such as carbon felt, glass fiber and continuous felt, and its weight is much lower than that of metal anode plate by resin infiltration and heating pultrusion.

Three, small surface resistance: the resistance value is less than or equal to 10 /m.

Four, flame retardancy: the oxygen index of ordinary FRP anode tube is above 33. Flame propagation rate (based on ASTM E-84 test) <25 is the first order of flame retardancy.

Five, easy maintenance, easy replacement: glass steel boards are assembled into the anode plate plate structure, plate and plate are fixedly connected by bolts, monolithic plate can be replaced.